| Sign In | Join Free | My hardware-wholesale.com |

|

| Sign In | Join Free | My hardware-wholesale.com |

|

| Categories | Conveyor Belt Vulcanizing Machine |

|---|---|

| Brand Name: | Qingdao Junlin Machinery Co., Ltd. |

| Model Number: | XLB-1400x10000x2 |

| Certification: | Quality Management System Certification Certificate; Specialized, Sophisticated, Distinctive, and Innovative Small and Medium-sized Enterprises ; High-tech Enterprise Certificate, etc. |

| Place of Origin: | Qingdao, Shandong Province, China |

| MOQ: | 1 set |

| Price: | USD 2,500–10,500/Set |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Supply Ability: | 500/year |

| Delivery Time: | 30~90days |

| Packaging Details: | wooden case |

| Type: | Rubber Conveyor Belt Production Line |

| Structure: | Horizontal |

| Our Techincial: | Own Professional Design |

| Voltage: | customized |

| Plug: | Harting or as request |

| Function: | VULCANIZER |

| Company Info. |

| Qingdao Junlin Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

| Liner Rewinding Unit | Green Belt Unwinding | Support Rollers Assembly | Front/Rear Drawing Unit |

|---|---|---|---|

| Max. Liner Rewinding Diameter: 600mm | Max. Green Belt Diameter: 3000mm | Support Roller Diameter: Ø80mm | Hauling Speed: 15 m/min |

| Max. Liner Rewinding Width: 1400 mm | Max. Width: 1400 mm | Support Roller Face Length: 1400 mm | Max. Hauling Width: 1400 mm |

Specifically engineered for continuous manufacturing processes

within the rubber products industry, including but not limited to:

• High-volume production of rubber conveyor belts

• Industrial-scale fabrication of rubber sheeting/plates

• Continuous processing of composite rubber materials

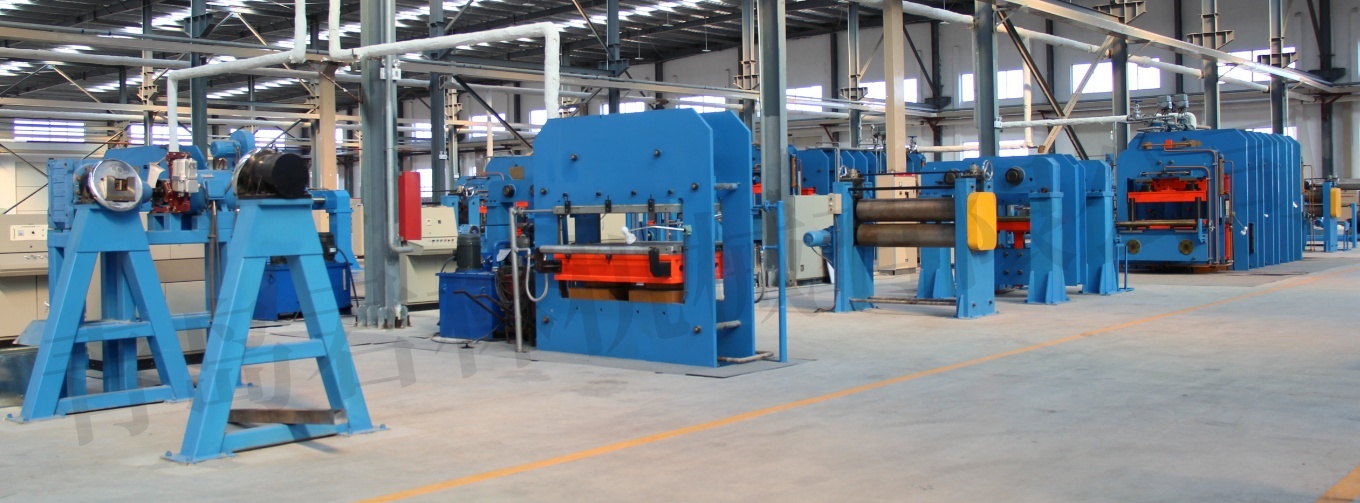

The integrated production system comprises:

Unwinding Unit - Automated material feeding system

Front Tension Control Station - Initial web handling and alignment

Main Processing Unit - Core calendering/laminating machinery

Intermediate Tension Control - Mid-line web stability management

Rear Tension Control - Output section tension regulation

In-line Inspection & Repair Station - Defect detection and correction

Rewinding System - Precision winding with tension control

High-Efficiency Stable Operation:

24/7 continuous production capability

≤0.5% downtime rate through robust design

• Adaptive Control System:

PLC-based programmable tension zones

Speed synchronization across all stations

• Durability-Engineered Construction:

Heavy-gauge steel frame with anti-vibration mounts

Wear-resistant components rated for 100,000+ operating hours

|